Happy new year followers and friends. It has been a long while since I wrote last. Spotty internet connection and a to do list as long as my left leg prevented me from taking the time. But now with most chores done and a shiny Starlink dish on the port transom I hope to find the time to update this more regularly. So what has been happening all this time, are we half way on our way to Thailand by now? Well, no….

I’ve been in Opua on the north island of New Zealand since the New Zealand borders opened, May last year. A lot has happened in this time. When I found a boat here in the marina she was in a sad state and a long journey of repair jobs started. First of the few things to make the boat livable again. Fix the water heater and fix the diesel heater, as New Zealand winter it’s bloody cold even here on the North island. See Only a poor or stupid man is cold

Then it was time for the bigger jobs. the bow thruster repairs, the anti-fouling, the sails, the deck repairs and the refit of the power-plant. I had some great help from the local tradies here in Opua.

The Opua boat builders helped me with the bigger jobs. The bow thruster repair and the deck repairs. We have been on the hard for almost 2 months to do the jobs that require the boat to be out of the water. Repairing the bow thruster was a huge job. The “drop in” replacement unit sent from Greece was supposed to be an exact replacement. Well nothing could be further from the truth. It wasn’t only slightly bigger than the original unit it was also a 24 Volt model not 12 Volt. The guys from the boat builders cut open the existing drop hatch and made it slightly bigger not an easy feat.

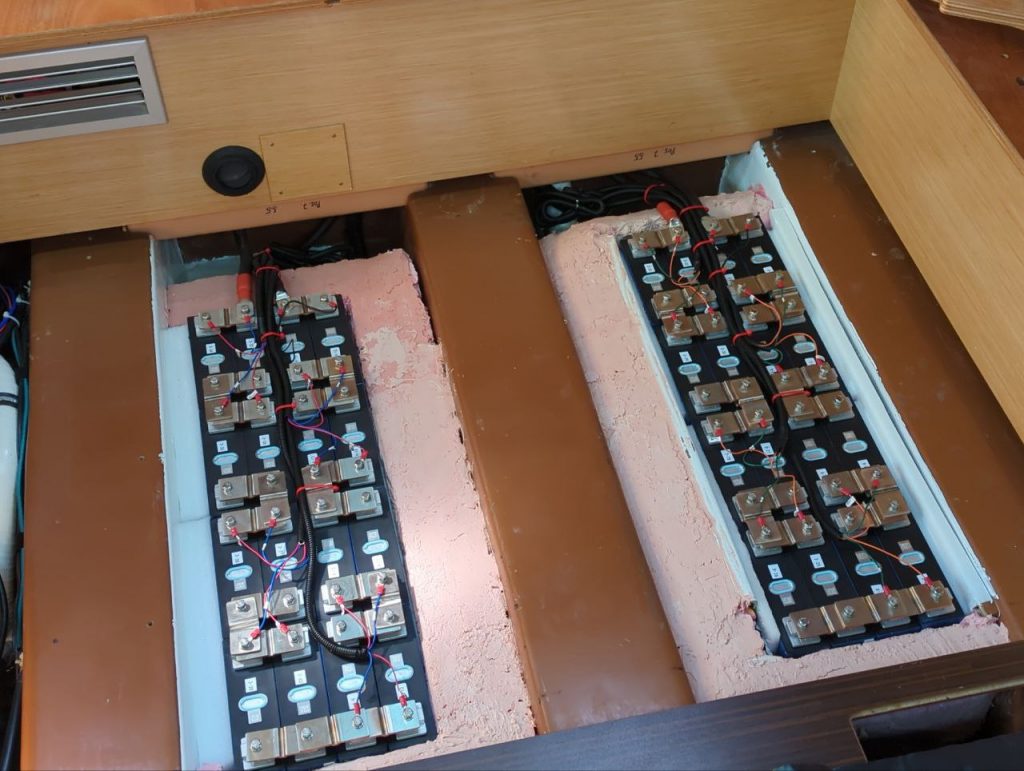

The difference in power requirements make me decide to also start the overhaul call of the batteries. This turned out to be very necessary. The existing AGM batteries were done and the original installation from Bavaria made no sense on many points. As we ripped out the existing batteries and cabling he found a battery bank of 1000 Amp hours divided over 6 batteries. No wonder that the existing battery bank have big difficulties getting to full charge.

I ordered a set of 32 lithium iron phosphate batteries from a local shop. There was quite a big price difference with getting the batteries from China myself but the convenience of having them here not having to deal with the import and picking them up from Auckland was worth the difference. But a few lithium batteries alone does not make a power plant. Quite a few other bits and pieces that needed to be added to the boat. Things like the battery management system the inverter and the computers to control it all. I decided to go with Victron set up using a 10 kVA inverter in combination with a 460 amp hours 48v battery bank. I was recommended to use an Orion Junior battery management system.

But a of the boat still run on 12 Volt. The winches, the navigation equipment and all lighting. There was still a need for a 12 V power bank to accommodate this. I decided to use a Scotty made by Saferi out of Australia. This little box provides me with 3000 Watts of 12 V DC power. It also takes the 12 volt feed of the alternator and pushes that back into the 48 volts battery bank and 48 Volts. Power going Up and Down the road, hence the name Scotty. Beam me up.

With this sorted there was the little issue of needing 24 volts or the new bow thruster. This was solved by adding a 12/24 series parallel switch as used in land Rovers and other vehicles equipped with a big winch on the front. This switch combines two huge 1050CA truck starting batteries into a 24v power pusher.

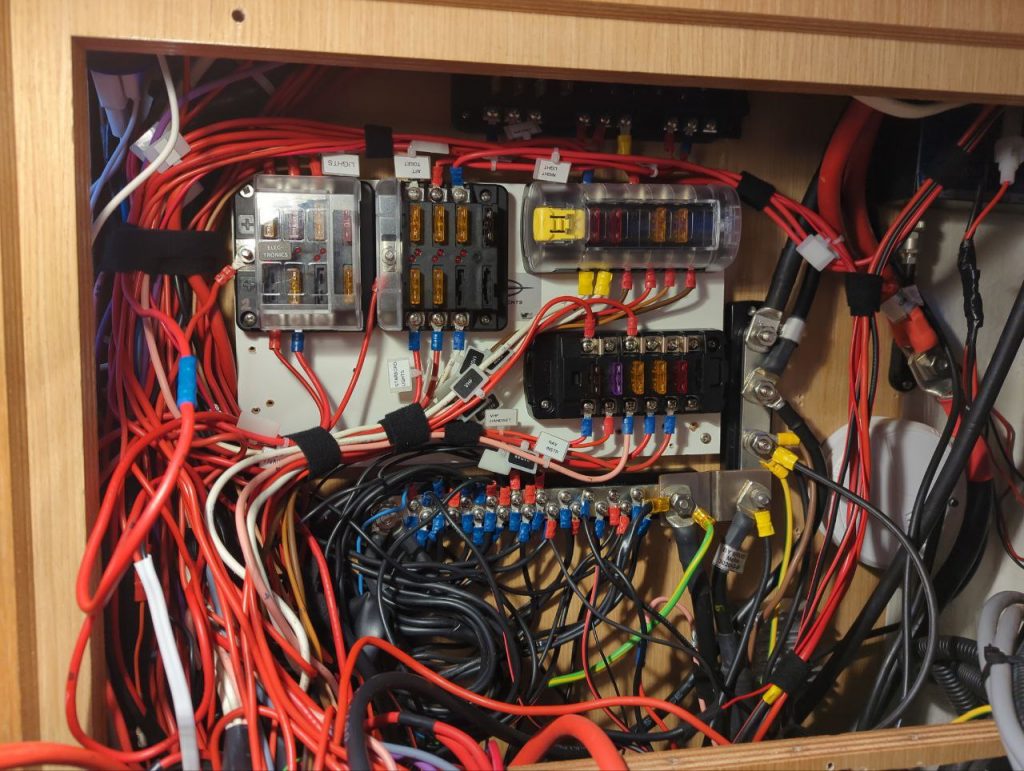

The guy from DC electrics in Kawakawa helped me install all this equipment. In the process we rewired pretty much the entire boat I think we pulled out 200 kg of unnecessary cables and of course half a ton of old DC AGM batteries.

To charge this rather large battery new battery bank we now depend on the aging generator and the 140 amp alternator off the main engine. To add some “green energy” into the mix I replaced the old and tired solar panels with a set of new three new 195 Watt panels from Juice. This new set of panels and delivers close to 600 Watt instead of 400 Watt. This turned out not to be enough to keep the power afloat during a day so I had to order two extra panels on the deck in front of the dodger. Ah Ma I is now equipped with close to 1000 W or solar in addition to all diesel powered regeneration options.

With all this beautiful new gear in place I found it also time to replace our broken DC switch panel. This was the factory standard DC switch panel (model 301) which came with the boat. It has been repaired many times to no avail. It misses information about water levels and some buttons were not functioning. So we also ripped this piece of antiquated equipment out and replaced it with a Czone digital switching solution and some BEP ultrasonic tank sensors for fuel and water. This gave me a good opportunity to clean up all the DC switching cabling, label everything and get a good understanding of how the boat is wired.

All this stuff is operational now but requires some fine tuning there are still a few issues to work out but these are mostly configuration issues on the Victron and the Orion BMS side.

Being in the Opua Marina for this long I made a great deal of new friends Among the Tradies but also among on the Yachties. I asked the local rigger from New Zealand yacht services to do a check up on the current standing rigging. It is close to 12 years old now and should theoretically be replaced. But AhMa has hardly been used over the years so the metalwork is still in pretty good shape. Nevertheless she would needed a few new bits up in the mast. A few sheave blocks have been replaced along with the block on the running backs stay which has never been working. I also made use of the opportunity to ask their help with the cleaning of all the winches. They all rattle as New now.

It was a big milestone to see the sails that I ordered more than two years ago from South East Asia sails finally go up in the mast. The custom Dragon ensign on the Genoa was flying proud and I can’t wait to put them to you use here in the bay of islands.

The weather in winter here on the North Islands is horrible. it reminds me of a Dutch summer rain, rain, followed by a storm, a day of sunshine and back to rain. But as the sunny periods increased I made use of the opportunity to repair the teak deck a few spots had lifted so needed replacing. Also the toe rail needed some love, after a bad repair job in the past it was now bulging out. We took all take off the teak from the toe rail and rejuvenated it with some sanding paper. Glued back on with the proper materials it looked like new. I also sanded back the lifting caulking on the deck and gave the whole deck a light sand. After this the top site also looked like new. The unstable weather makes this work last longer than anticipated but the results are good.

All the rain didn’t make for a good opportunity to hunt for leaks on the boat. And there were quite a few. Deck fittings with aged caulking started to allow little drips of water to enter the aft of the boat. So armed with a tube of new caulking and some 5200 I closed every little crack that I could find.

Finally last month I was ready to leave the work dock. The marina have a spot for me in the main marina where I could stay for a while. But while moving the boat from K dock to G dock I noticed that the rudders were unusually hard to steer they also made very unpleasant squeaking and grinding noises. At first he thought that the autopilot had a blocked magnetic clutch. But after further investigations turned out not to be the case. Thank goodness , as replacing a clutch on the autopilot would be a very difficult and expensive job. It turned out that the rudder bearings on the port rudder had collapsed . A big disappointment as now I need to come out of the water again to drop the rudders. The necessary parts are in the mail so I hope that they arrive early next week. I have another haul out booked for the 11th of January.

I do hope this that this is the last of the big repair jobs so I can finally leave this place and explore the bay of islands.